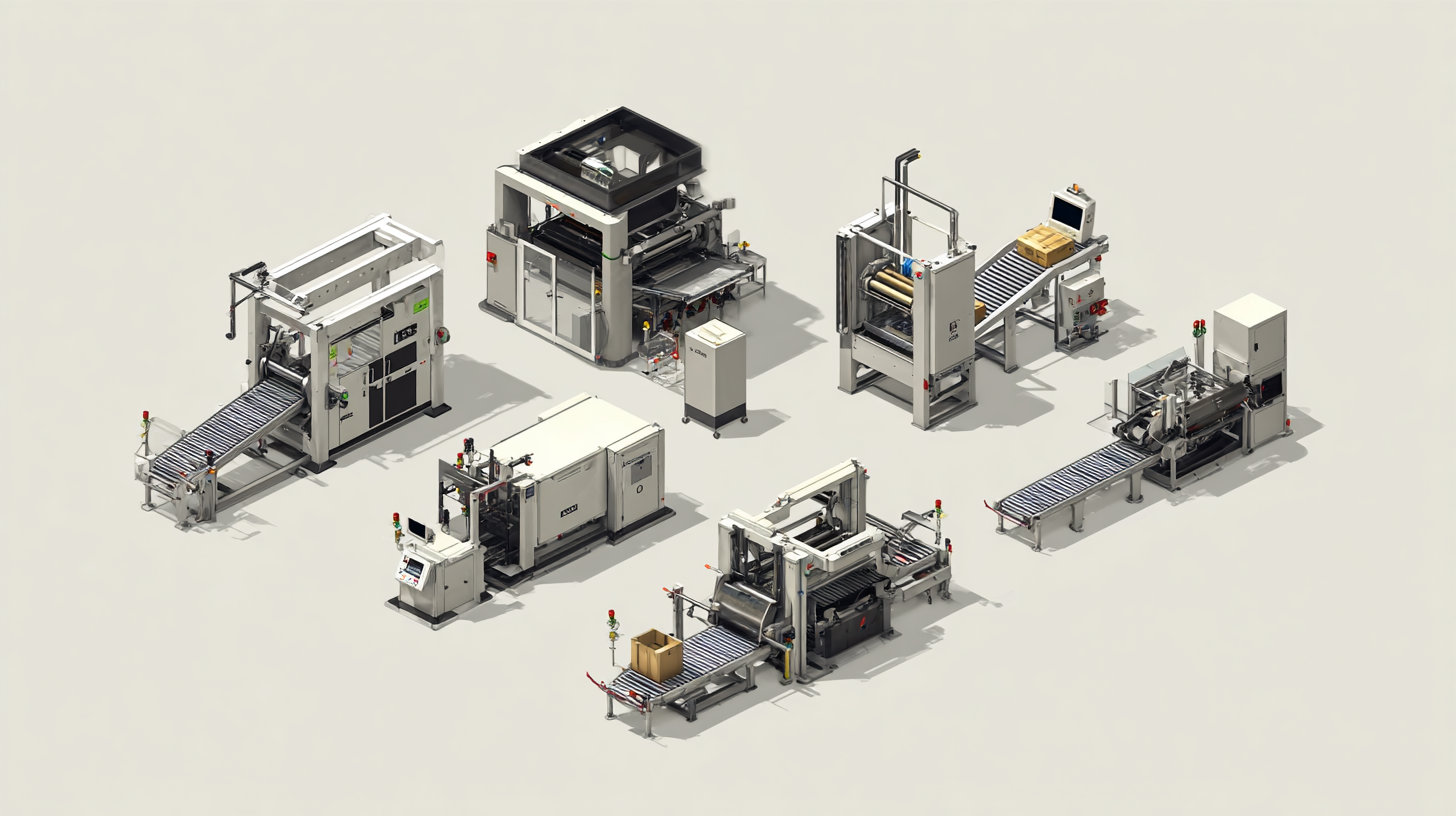

Understanding Industry Standards: What Defines the Best Packaging Equipment?

As the packaging industry evolves rapidly, understanding the key standards that define the best packaging equipment is crucial for businesses aiming to enhance their operational efficiency and maintain a competitive edge. According to a recent market analysis for 2025, the global packaging equipment market is projected to reach approximately $50 billion, with a CAGR of over 5%. Industry reports highlight the increasing demand for automation and flexible packaging solutions, emphasizing the significance of reliability, speed, and versatility in packaging machinery. Companies that invest in equipment compliant with industry standards not only improve productivity but also ensure safety and sustainability throughout their operations. In this context, exploring what truly distinguishes the best packaging equipment becomes essential for stakeholders aiming to align with these pivotal market trends.

Key Innovations in Packaging Equipment: What to Look For

In the fast-evolving world of packaging, staying informed about key innovations is essential for businesses aiming to enhance efficiency and sustainability. According to a recent report by Smithers Pira, the global packaging equipment market is anticipated to grow by over 4% annually, driven by advancements in automation and smart technology. When evaluating packaging equipment, look for systems that integrate IoT features, allowing for real-time monitoring and data collection. This integration can significantly reduce downtime and improve productivity.

Tip: When selecting packaging equipment, prioritize machine compatibility with existing processes. This ensures seamless integration and minimizes disruptions during setup. Additionally, explore options that emphasize eco-friendly materials and reduced energy consumption. Industry studies indicate that packaging machinery that uses fewer resources can cut operational costs by up to 30% while aligning with global sustainability goals.

Look for solutions that offer modular designs, enabling manufacturers to adapt their systems to varying production needs. As per a report from Grand View Research, customizable packaging lines are becoming increasingly popular, with 60% of companies prioritizing flexibility in their equipment choices. This adaptability not only allows for a diverse product range but also future-proofs operations in a market that's constantly evolving.

Essential Features of High-Quality Packaging Machinery

In the fast-evolving landscape of packaging technology, understanding what defines high-quality packaging machinery is paramount for businesses seeking efficiency and sustainability. Essential features of top-tier packaging equipment include versatility, reliability, and advanced automation capabilities. For instance, the global MasterBatch market is projected to reach a substantial valuation of $2.79 billion in 2024, signifying a robust demand for innovative packaging solutions that integrate these qualities. As industries grow, the necessity for adaptable machinery that accommodates diverse product types will only heighten.

When considering new packaging machinery, prioritize equipment that offers scalability. This feature allows businesses to adjust production rates in response to market demand fluctuations. Additionally, investing in machinery with energy-efficient designs can significantly reduce operational costs. With the BOPP film market also poised for growth—from $1.97 billion in 2025 to $2.77 billion by 2033—incorporating sustainable practices in packaging processes can enhance not just efficiency but also brand reputation.

Finally, ensure that the machinery is equipped with smart technology for real-time monitoring and diagnostics. This capability not only minimizes downtime but also provides critical data insights to optimize production workflows. Embracing these features will position businesses to thrive amid the competitive packaging landscape while meeting the growing standards of quality and sustainability.

Evaluating Packaging Equipment Efficiency: Metrics That Matter

When evaluating packaging equipment efficiency, it's crucial to focus on several key metrics that can significantly impact productivity and cost-effectiveness. One of the primary metrics is Overall Equipment Effectiveness (OEE), which considers the availability, performance rate, and quality of the packaging process.

By analyzing OEE, companies can identify areas for improvement, reduce downtime, and enhance throughput, leading to a more streamlined packaging operation.

Another important metric is the Return on Investment (ROI), which assesses the financial benefits of implementing new packaging equipment relative to its cost. A higher ROI indicates that the equipment is not only efficient but also contributes positively to the company’s bottom line. Additionally, considering the cycle time—the time it takes to complete a packaging process—is essential for optimizing workflow.

By monitoring and minimizing cycle times, businesses can meet customer demands more effectively while maintaining high-quality standards. Prioritizing these metrics ensures that organizations not only select the best packaging equipment but also maximize their operational efficiency.

Sustainability in Packaging: Trends and Standards

Sustainability has emerged as a cornerstone in the evolution of packaging standards, driving innovation and reshaping consumer expectations. As the industry moves towards 2025, a clear trend is evident: companies are increasingly adopting sustainable materials, such as seaweed-based packaging, which not only addresses environmental concerns but also aligns with the growing consumer demand for eco-friendly solutions. This shift is complemented by advancements in edible packaging technology, making sustainability both a practical and appealing choice for businesses.

Moreover, the food packaging sector is responding to the challenge of plastic reliance by exploring alternative models that emphasize recyclability and material innovation. The focus on collaborative partnerships between brands and suppliers is facilitating the development of packaging solutions that meet new regulatory requirements while enhancing consumer convenience. With sustainability at the forefront, the packaging industry is not just adapting to change; it's leading a transformative movement that promises a greener future for the planet.

Understanding Industry Standards: What Defines the Best Packaging Equipment? - Sustainability in Packaging: Trends and Standards

| Aspect | Description | Trend/Standard | Impact on Sustainability |

|---|---|---|---|

| Materials | Use of sustainable, recyclable, or biodegradable materials. | ISO 14021 - Environmental Labels and Declarations | Reduces environmental footprint and promotes recycling. |

| Energy Efficiency | Reduction in energy use during production and transport. | Energy Star Certification | Lower carbon emissions and operational costs. |

| Design for Recycling | Packaging designed to be easily recyclable. | SPC's How2Recycle Label | Encourages consumer participation in recycling programs. |

| Life Cycle Assessment | Assessment of the environmental impact throughout the package lifespan. | ISO 14040 - Life Cycle Assessment | Informs better environmental decisions. |

Future-Proofing Your Packaging: Adapting to Industry Changes

In today's rapidly evolving marketplace, future-proofing your packaging is essential for staying competitive. Adapting to industry changes requires a proactive approach, as emerging trends and technologies can significantly affect production efficiency and customer satisfaction. Businesses must monitor and assess new developments, such as sustainable materials and automation solutions, to maintain relevance and meet consumer demands.

Moreover, investing in versatile packaging equipment is critical for flexibility. This means selecting technology that can easily accommodate changes in product sizes, formats, and materials. By integrating smart packaging solutions, companies can also gain real-time data insights, enabling them to make informed decisions and quickly pivot strategies as the industry landscape shifts. Embracing innovation will not only enhance operational efficiency but also solidify a brand's position in the market, ensuring resilience against future challenges.

Understanding Industry Standards: Best Packaging Equipment

This bar chart represents the importance ratings of various aspects of packaging equipment based on industry standards, highlighting efficiency and durability as the most critical factors.